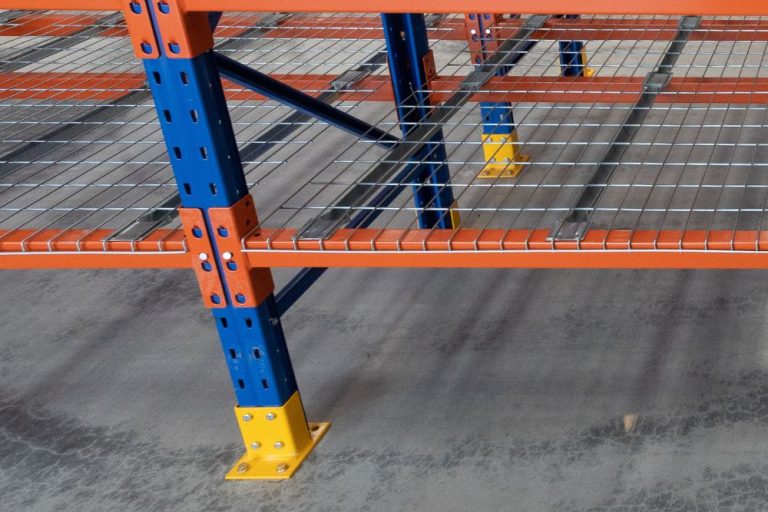

Safetylock Frames have been engineered to maximise structural capacity and operating safety. The upright shape is designed to maximise the effectiveness of the steel.

The shape was a result of several tests on various shapes, sizes and steel grades.

The beam connection slot has been minimised to reduce the quantity of steel removed from the upright and increase safety factors and resistance to accidental damage.

SafetyLock Frame Bracing is of high-grade steel and is a specially rolled-lipped channel 36×25 to maximise frame rigidity and overall strength.

All frames are fully braced from bottom to top at the same pitch. We do not recommend increasing the pitch at the upper part of frames or reducing bracing members.

SafetyLock Boxed Beams are formed of two steel-lipped channels that are crimped and interlocked at all four corners. The reinforced corners prevent the opening of the beam sections and provide maximum resistance to accidental horizontal impact and overloading during use.

Load Beam Deflection – Safetylock Load Beams are designed for a maximum deflection of 1/200 when loaded to the specified load limits.

Load Beam Safety Factors – The popular size beam 85mm wide and 2591mm long, designed to support two Australian Standard Pallets weighing 1050 kg each, has been repeatedly in situ tested up to buckling point to determine ultimate strength and, every test showed a safety factor in excess of 2:1, before buckling of the beam section or connector resulted.

In layman’s terms, test weights over 4000kg were applied and no buckling or shear was evident at this limit. However, we do not recommend the loading of support beams in excess of the specified SWL, as there are several other aspects that must be considered when computing capacities and safety factors.